RPZ Valve Certified Testing

Introduction

RPZ valves, or Reduced Pressure Zone valves, are important for preventing backflow and keeping our drinking water safe. They make sure that dirty water doesn’t mix with clean water. These valves are especially necessary in places like businesses and apartment buildings where there’s a higher risk of contamination.

Contact Duo Plumbing – RPZ Valve Certified Testing Experts for Your Backflow Prevention Needs!

It’s crucial to hire certified testers who know how to check and maintain these valves properly. This is not only required by local laws but also ensures that the RPZ valves are working correctly.

In this article, we aim to help you find trustworthy Staten Island RPZ Valve Certified Testing. We’ll explain why these valves are important and why certification matters. With this knowledge, you’ll be able to make better choices regarding your backflow prevention needs.

Table of Contents

Understanding RPZ Valves

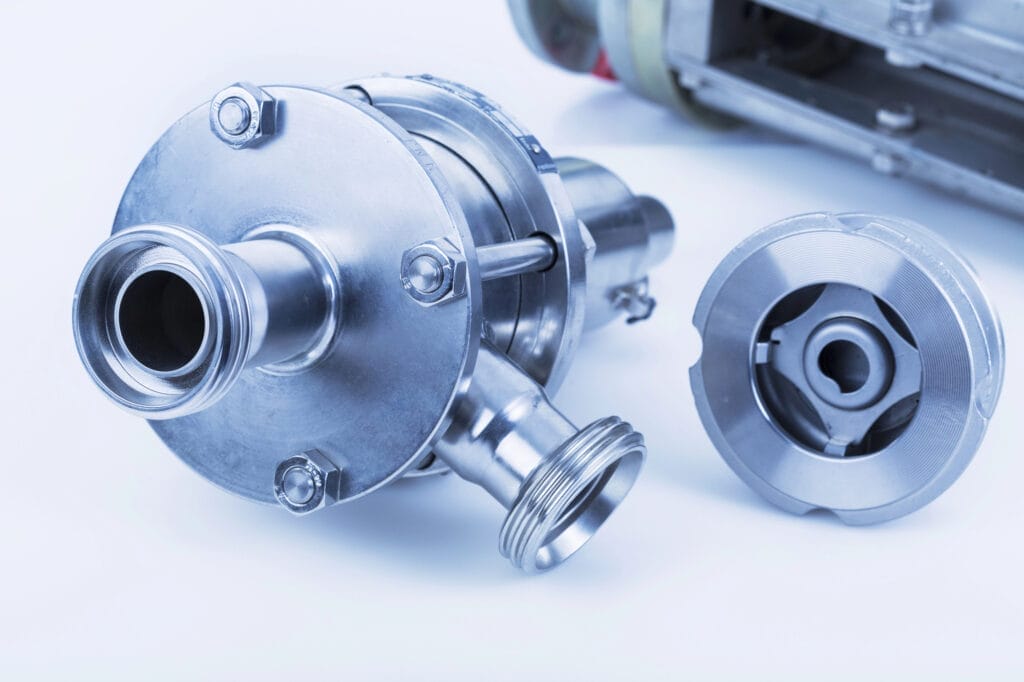

RPZ Valve (Reduced Pressure Zone Valve) is a type of backflow preventer designed to protect water supplies from contamination. It functions by maintaining a zone of reduced pressure between two check valves, ensuring that any backflow does not enter the clean water supply. A relief valve located between the check valves opens to discharge water, further preventing contamination.

How RPZ Valves Differ from Other Backflow Devices

RPZ valves offer superior protection compared to other backflow prevention devices due to their dual-check mechanism and relief valve:

- Double Check Valve Assembly (DCVA): Uses two check valves but lacks a relief valve, making it less effective against high-hazard conditions.

- Pressure Vacuum Breaker (PVB): Prevents back-siphonage but is ineffective against back pressure.

- Spill Resistant Pressure Vacuum Breaker (SVB): Similar to PVB but designed to minimize spillage during operation.

Common Backflow Prevention Devices in NYC

Contact Duo Plumbing – RPZ Valve Certified Testing Experts for Your Backflow Prevention Needs!

In Staten Island, several types of backflow prevention devices are commonly installed:

- RPZ Valves: Preferred for high-risk applications such as commercial properties and multi-family residential buildings.

- Double Check Valve Assemblies: Often used in low-risk environments where the potential for contamination is minimal.

- Pressure Vacuum Breakers: Typically found in irrigation systems and outdoor plumbing where back-siphonage risk is higher.

Understanding the specific function and advantages of RPZ valves helps you make informed decisions about protecting your water supply.

The Importance of Certification for Testers

Hiring experts for RPZ Valve Certified Testing is crucial for ensuring the effectiveness and safety of backflow prevention systems. Certified testers undergo rigorous training and evaluation through the ASSE certification process, which stands for the American Society of Sanitary Engineering. The ASSE certification validates that a tester has the necessary knowledge and skills to perform accurate inspections and maintenance on RPZ valves.

Benefits of Hiring Certified Professionals:

- Expertise: Certified testers possess specialized knowledge in identifying potential issues and performing precise repairs.

- Compliance: They ensure that the testing process adheres to local regulations, helping property owners avoid legal complications.

- Safety: Properly tested RPZ valves effectively prevent contamination of potable water supplies, safeguarding public health.

Contact Duo Plumbing – RPZ Valve Certified Testing Experts for Your Backflow Prevention Needs!

The role of certification extends beyond technical proficiency. In Staten Island, compliance with local regulations often mandates that only RPZ Valve certified testing and professionals conduct backflow testing. This requirement ensures a standardized approach to maintaining water quality across various properties, from commercial businesses to multi-family residential areas.

Engaging a qualified plumber who is certified not only guarantees adherence to safety standards but also provides peace of mind. Knowing that RPZ Valve certified testing experts are handling your RPZ valve testing means you can trust in their competence and thoroughness.

RPZ Valve Certified Testing Process Explained

Understanding the backflow testing process is crucial for maintaining a safe and compliant water system. Here’s a step-by-step breakdown of what to expect during a backflow test:

1. Initial Inspection

The RPZ Valve certified testing tester begins by visually inspecting the RPZ valve and its surroundings for any obvious signs of damage or wear.

2. Shutting Off Water Supply

The main water supply to the building is shut off to prevent any accidental contamination during the testing procedure.

3. Attaching Testing Equipment

Specialized gauges and meters are connected to the RPZ valve to measure pressure differentials and ensure proper functionality.

4. Pressure Testing

The tester conducts a series of pressure tests to check whether the valve is maintaining appropriate pressure levels, critical for preventing backflow.

5. Identifying Issues

Any discrepancies in pressure readings can indicate common issues such as faulty check valves, relief valve problems, or leaks within the assembly.

6. Recording Results

Detailed results of the test are recorded, including any identified issues that require repair or replacement.

7. Restoring Water Supply

After testing is completed, the water supply is turned back on, and the system is closely monitored to ensure it returns to normal operation without any leaks or pressure issues.

8. Reporting and Compliance

A comprehensive report is generated and often submitted electronically for regulatory compliance purposes.

Frequency of Testing

Annual backflow testing is generally recommended, but some systems may require quarterly checks based on local regulations and hazard levels. Regular testing helps identify potential issues before they become severe, ensuring continuous protection against contamination.

Contact Duo Plumbing – RPZ Valve Certified Testing Experts for Your Backflow Prevention Needs!

By adhering to this structured approach, you can maintain a reliable defense against backflow incidents and uphold public health standards.

RPZ Valve Certified Testing in Staten Island

To find RPZ Valve certified testing in Staten Island, start by exploring local directories and online resources. Websites like Yelp and Angie’s List often feature reviews and ratings for backflow testing services, giving you a sense of each provider’s reliability and customer satisfaction.

Tips for Locating Experienced Testers

- Check Certification: Ensure the tester holds ASSE certification. This guarantees they have undergone rigorous training and adhere to industry standards.

- Ask for References: Request testimonials or references from previous clients to gauge the tester’s expertise and reliability.

- Verify Licenses: Confirm that the service provider is licensed to operate in New York State. This is crucial for compliance with local regulations.

- Look for Specialized Experience: Opt for testers who specialize in RPZ valves, as they will be more familiar with the specific requirements and challenges associated with these devices.

Factors to Consider When Choosing a Service Provider

- Experience Level: Seasoned professionals are likely to identify issues more accurately and provide effective solutions.

- Service Range: Some companies offer additional services such as repair and maintenance, which can be beneficial if your RPZ valve requires more than just testing.

- Cost Transparency: Choose a provider who offers clear pricing structures. Hidden fees can inflate costs unexpectedly.

- Availability: Emergency situations demand prompt attention. Ensure the tester provides flexible scheduling or 24/7 support.

By keeping these points in mind, you can find RPZ Valve certified testing in Staten Island who offer reliable, comprehensive services that meet your needs.

Cost Considerations for Backflow Testing Services

Factors Influencing the Cost of Testing Services

The cost of backflow testing services can vary based on several factors:

- Device Type: Different types of backflow preventers such as Reduced Pressure Zone Assembly (RPZD), Double Check Valve (DCA), and Pressure Vacuum Breakers (PVB) have distinct testing requirements.

- Location: Accessibility and the complexity of reaching the device can affect labor costs. Devices situated in hard-to-reach areas may incur higher charges.

Repair vs Replacement Costs

When it comes to maintenance, it’s crucial to weigh the costs of repairs versus replacement:

- Repair Costs: Typically include labor and parts. Regular maintenance can extend device lifespan, making repairs a cost-effective option for minor issues.

- Replacement Costs: Often necessary when a device is beyond repair or obsolete. Factors such as valve size, condition, and availability of parts influence the total expense.

Understanding these cost considerations helps you make informed decisions about maintaining your backflow prevention systems efficiently.

Benefits of Regular Backflow Testing on Water Quality and Public Health

Regular backflow testing plays a crucial role in maintaining water quality and safeguarding public health. Ensuring timely tests can:

- Prevent Contamination: Backflow preventers stop non-potable water from mixing with the clean water supply. This is essential for avoiding the transmission of harmful bacteria, chemicals, and other contaminants.

- Protect Public Health: Untested or faulty backflow devices can lead to serious health issues, including gastrointestinal illnesses and other waterborne diseases. Regular testing mitigates these risks by identifying and rectifying potential hazards.

- Maintain Clean Water Supply Systems: Consistent testing ensures the integrity of municipal and residential water systems, preventing costly repairs and ensuring compliance with health regulations.

- Early Detection of Issues: Routine tests help in detecting wear and tear or malfunctioning parts early, allowing for timely repairs that extend the lifespan of backflow prevention devices.

Investing in regular backflow testing is not just about compliance; it’s a proactive measure to ensure the safety and well-being of your community.

Contact Duo Plumbing – RPZ Valve Certified Testing Experts for Your Backflow Prevention Needs!

Ensuring the safety and compliance of your RPZ valves is critical for preventing water contamination in Staten Island. RPZ Valve certified testing expertise and adherence to local regulations, providing peace of mind.

For reliable backflow testing services, contact Duo Plumbing for expert assistance with your backflow prevention needs. Their professional team offers comprehensive services, including electronic reporting and 24/7 support, ensuring your systems are well-maintained and compliant. Reach out today to contact RPZ Valve certified testing and safeguard your water quality and public health.